Ingxenye 2: Sizokwenzani ekwakhiweni kotshwala?

2.1 I-Brewhouse: Ihambisana kakhulu nesicelo sakho sokuphisa.

Ingxenye ye-Brewhouse iyingxenye ebaluleke kakhulu ekukhiqizeni utshwala obuphelele, obuhlobene ngokuqondile ne-wort kanye nekhwalithi kabhiya.Idizayini ye-brewhouse kufanele ilandele ngqo iresiphi yakho yokuphisa, isb isilinganiso samandla adonsela phansi kabhiya/i-plato.Qiniseka ukuthi inqubo ye-Mash noma ye-lautering ingaqedwa ngesikhathi esifanele.

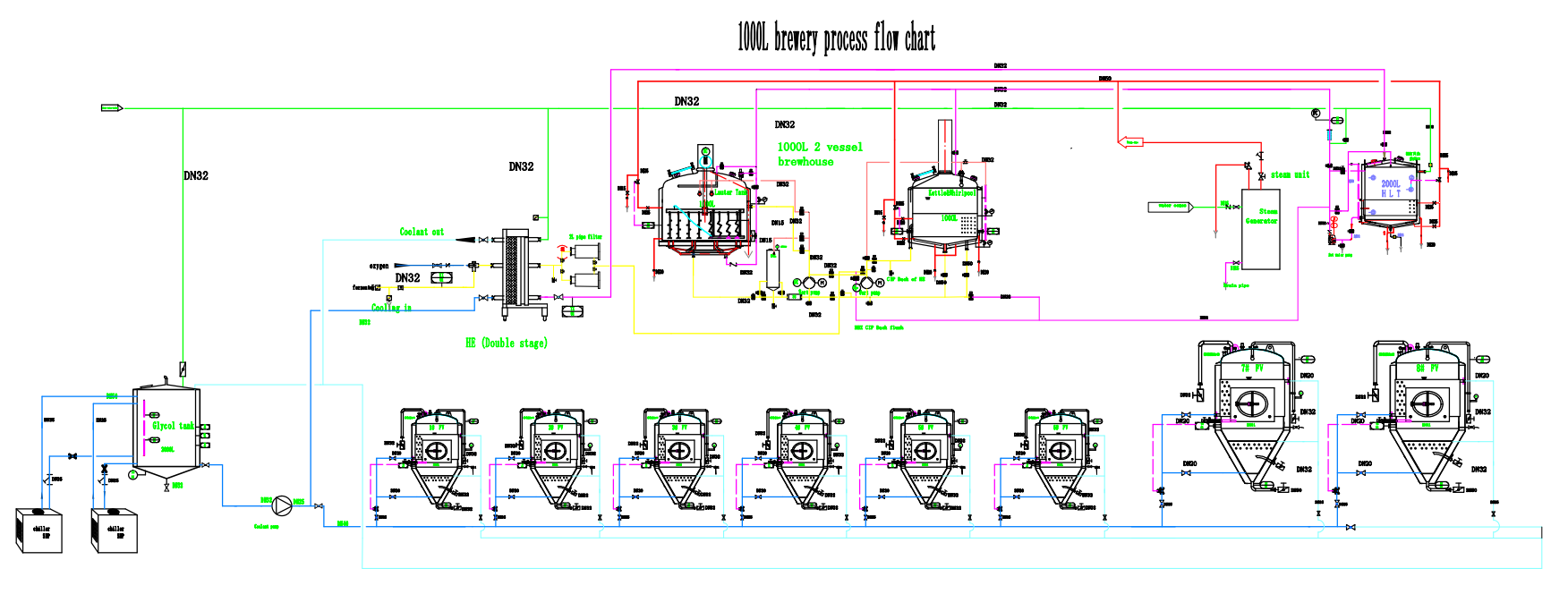

Njengesampula nje ye-10BBL uhlelo lokuphisa utshwala.

Ithangi le-lauter: Ububanzi bethangi le-lauter buyi-1400mm, lapho i-wort ingama-degrees angu-13.5, inani lokuphakela i-malt lingu-220KG, okokusebenza okusebenzisa ukusebenza kahle kungama-75%, kanti ukujiya kongqimba lokusanhlamvu kungu-290mm;indawo yokuhlunga ingu-1.54m2, futhi isivinini sokuhlunga singu-0.4m/s;Izinga lokuvula lesisefo liyi-12%, futhi kuneziteshi eziyisi-6 ze-wort ku-lauter tank.

Ngokusekelwa yilezi mingcele, kuyaqinisekiswa ukuthi isikhathi sokuhlunga siqedwa phakathi namahora angu-1.5, futhi kungaqinisekisa ukuthi ungathola i-wort ecacile.

Uma i-wort iyi-plato engu-16, inani lokuphakelayo lingu-260KG, umthamo wethangi usebenzisa u-80%, futhi ugqinsi lwebhedi lokusanhlamvu luyi-340mm.Lokho okokuqinisekisa ukuthi ukushuba kongqimba lwesihlungi kuhlangabezana nezidingo zokuphisa, akuthinti isivinini sokuhlunga futhi kuqinisekisa ukusebenza kahle kokukhiqiza.Okokugcina ukuze kuthuthukiswe okukhiphayo ngesikhathi seyunithi ngayinye ngokunciphisa isikhathi sokuhlunga.

Igedlela elibilayo: Idizayini yevolumu yeketela isuselwe ku-1360L wort ngaphambi kokubilisa, futhi umthamo osetshenziswayo ungama-65%.Ngenxa yokuthi i-wort concetration iphakeme kakhulu kwamanye amazwe, ifomu liyoba luningi lapho libilisa.Ukuze uvimbele ukuchichima kwegwebu eketelani ngesikhathi sokubilisa, sisebenzisa umsebenzi wokujikeleza okuphoqelekile ukuze sithuthukise izinga lokuhwamuka ukuze siqinisekise ukuthi izinga lokuhwamuka liyi-8-10% futhi sithuthukise ukubilisa.Ukujikeleza okuphoqelekile ngeketela kusiza ukukhulisa ukuhwamuka, kanye nesimo se-DMS nokuqukethwe ngaphakathi kwe-30PPM, kuzonciphisa ukulayishwa kokushisa nokuqinisekisa ukuzinza kwe-wort chroma nokugwema ukusabela kwe-wort Maillard.

2.2 Ukusetshenziswa kwamandla okuphansi endaweni yokuphisa utshwala

I-Condensor System: Igedlela elibilayo lisebenzisa uhlelo lokubuyisela ukujiya kwesitimu, luzosiza ukuthuthukisa ukutholakala kwamanzi futhi longe ukusetshenziswa kwamanzi nogesi kuyo yonke indawo yokuphisa utshwala.Izinga lokushisa lamanzi ashisayo alulame lizungeze u-85℃, kanye namandla okubuyisela amanzi ashisayo ku-150L kuqoqo ngalinye;Lokho kusho ukuthi izokonga i-electic 18kw iqoqwana ngalinye lokushisa kwamanzi ukusuka ku-25-85℃.

I-Wort cooler: Indawo yokushintsha ukushisa kwewort ibalwa ngenqubo yokuphisa bese iqeda inqubo yokupholisa ngemizuzu engama-30-40, kanye nezinga lokushisa lamanzi ashisayo libe ngu-85℃ ngemva kokushintshisana kwe-heax, ukusebenza kahle kokushintshisana kokushisa okungaphezu kuka-95%.Ngakho-ke, sizoqinisekisa ukutholwa kwamandla aphezulu kanye nezindleko zokukhiqiza eziphansi.

2.3 Ukuphisa kalula kanye nokunciphisa ukugcinwa kwinqubo yokuphisa

2.3.1 I-strainer ephindwe kabili imisiwe, uma kwenzeka iklayenti liphisa ubhiya we-hoppy kakhulu.Ngakho-ke siletha isiqinisekiso esihle kusishintshi sokushisa kwepuleti, okuyingxenye enzima kakhulu yokuhlanza.

2.3.2 Iphampu ekabili iyadingeka kuyunithi ye-glycol, ukuze uthole isiqinisekiso esihle uma kukhona isicelo sokugcina, iphampu ngayinye ingashintshwa kalula ukuze kugcinwe ukukhiqizwa kuqhubeka.

2.3.3 I-Dual chiller emisiwe, enenjongo efanayo njengepompo ye-glycol.

2.3.4 Iphampu ye-Glycol isebenzisa iphampu yokucindezela njalo futhi igcine ingcindezi efanayo kuwo wonke amapayipi e-glycol, ivikele i-soleniod valve futhi yandise ukuphila okusebenzayo.

Yonke le mininingwane ingeyomsebenzi ozinzile wokwenza utshwala obuphelele, futhi ikulethele ulwazi oluhle enqubweni yokuphisa.

Isikhathi sokuthumela: Sep-25-2023